Mesh (for painted wall)

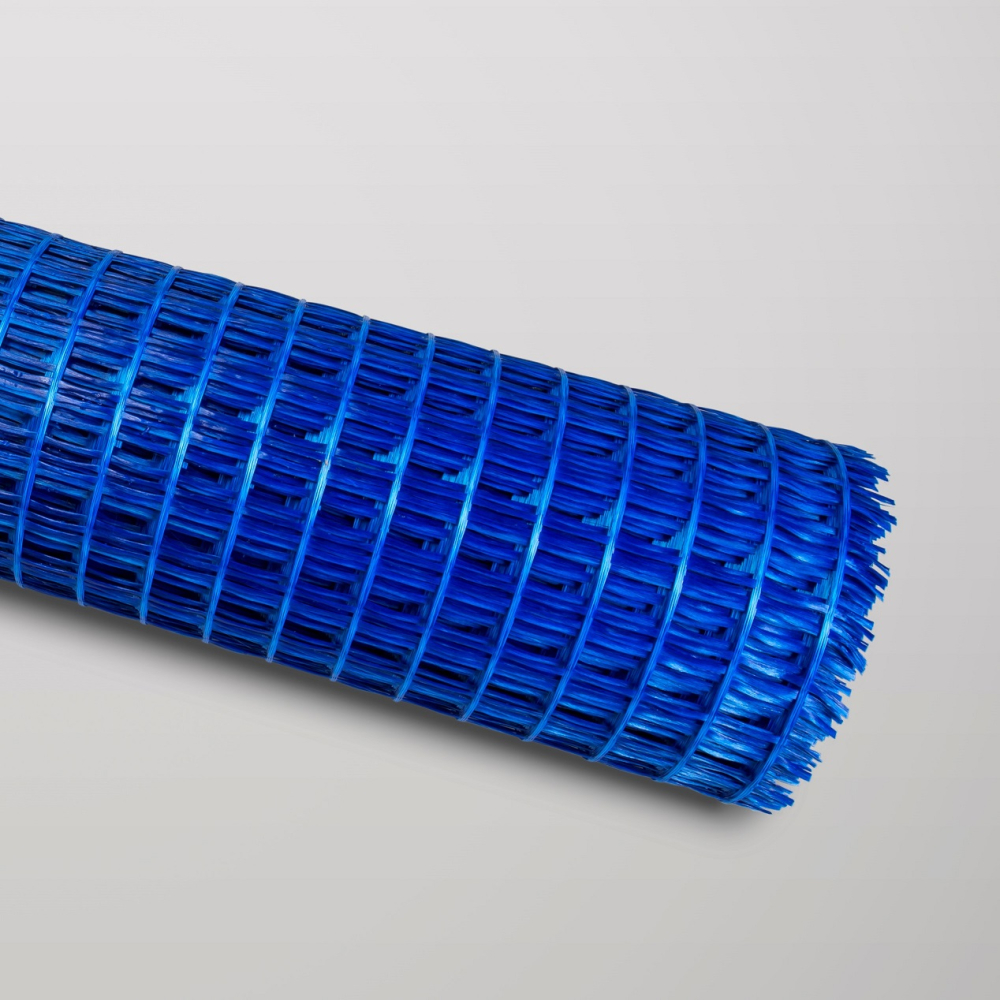

ADFORS produces different kinds of mesh knitted by glass yarn.

Its characteristics like high tensile strength, low elongation and thermal resistance enable products to be used in different applications like crack prevention for plaster or mortar walls and mortar floors.

Differently from steel wire mesh, glass fiber mesh can be delivered in roll form and be easily cut by normal scissors.

◆Glass fiber mesh for the purpose of crack prevention in plater or mortar walls

◆Glass fiber grid for the purpose of crack prevention in mortar floors and self-leveling layer

Product examples |

||

|

Biaxial mesh (for walls)

|

|

After applying the base coat to the exterior wall, the mesh is laid down, and the finishing material is applied from above. |

Triaxial mesh (for walls)

It has a higher crack suppression effect than conventional biaxial mesh, and is ideal for areas where cracks are particularly likely to occur, such as the corners of openings and the joints of foundations and structures. |

|

Biaxial grid (for floor)

|

Installation of grid

|

|

Adfors Vertex Mesh central page (English)